Come visit us! We will be located in Hall B at Booth 7553 and 7953

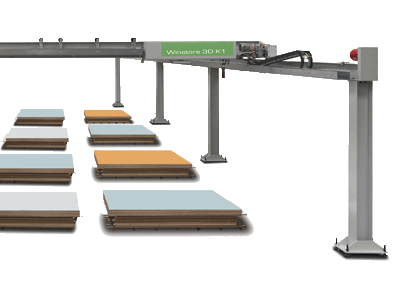

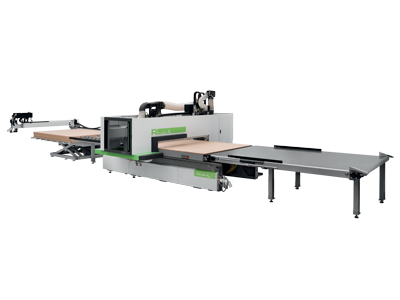

At IWF, we will demonstrate stand alone machines, as well as TWO automated solutions designed to simplify your production. Leverage the power of Biesse technology for seamlessly integrating additional production machinery, robotic automation, and after-sales support, ensuring efficient Machine-to-Machine integration and success in your manufacturing processes.

• Learn how machine integration and digital connectivity will help maximize your shop’s efficiency

• Explore our Software solutions for 360 degree management of scheduling and tracking of your production

• See firsthand how integrating SOPHIA IoT and PARTS Sophia diagnostics tools will optimize the performance and production of your machinery

• Talk with our technical experts about our industry leading on-site and on-line after sales support

Talk with our industry experts at IWF. It’s never too early to start planning your company’s ability to maximize profits, reduce labor costs, improve safety, increase efficiencies, and ensure your competitive advantages. Regardless of your shop size, we have scalable and flexible solutions to meet your needs.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil

.png)