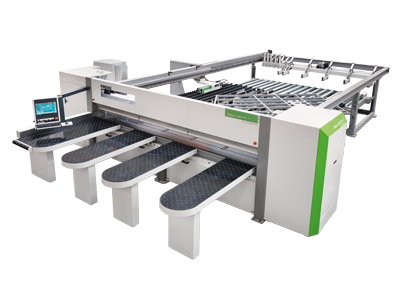

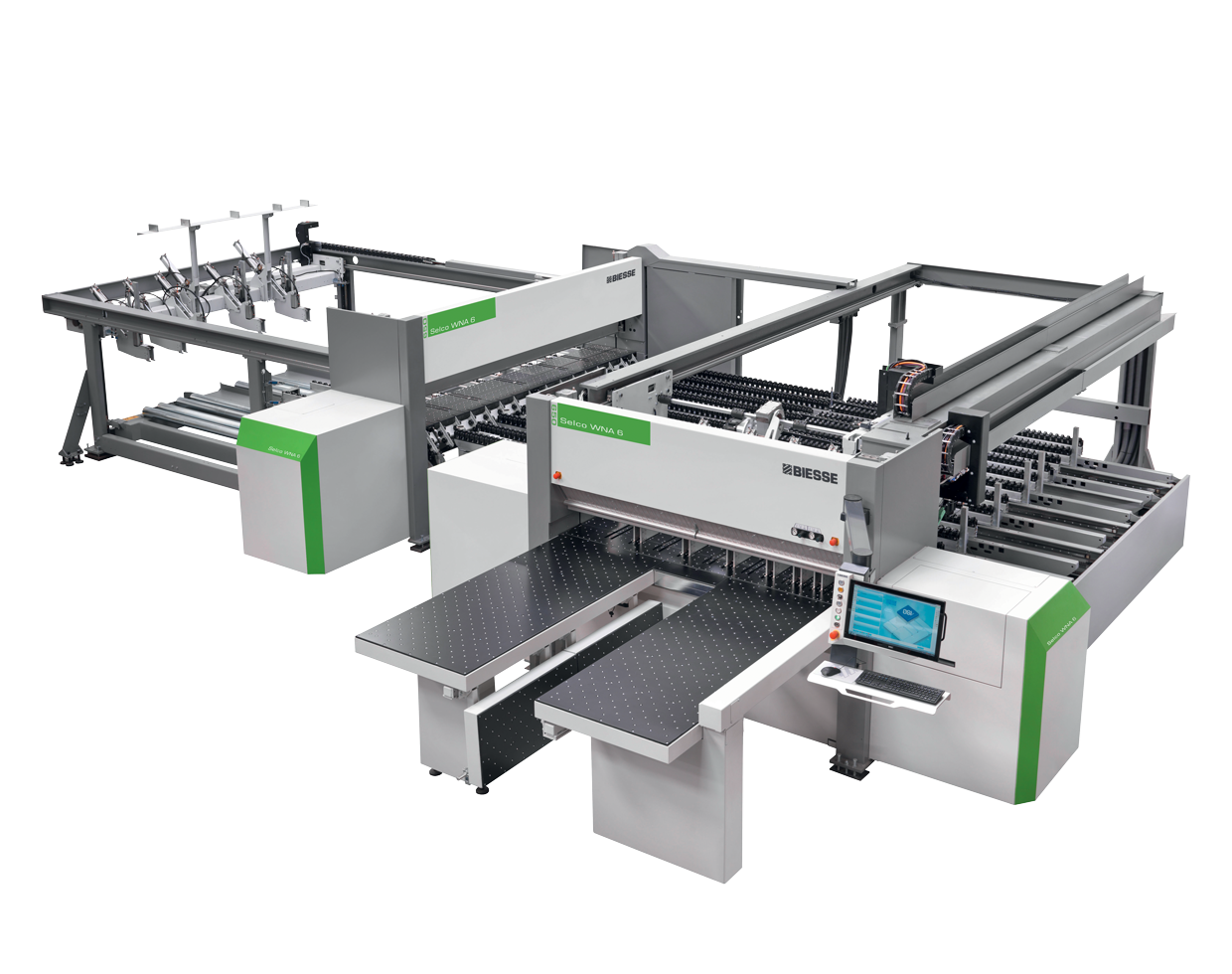

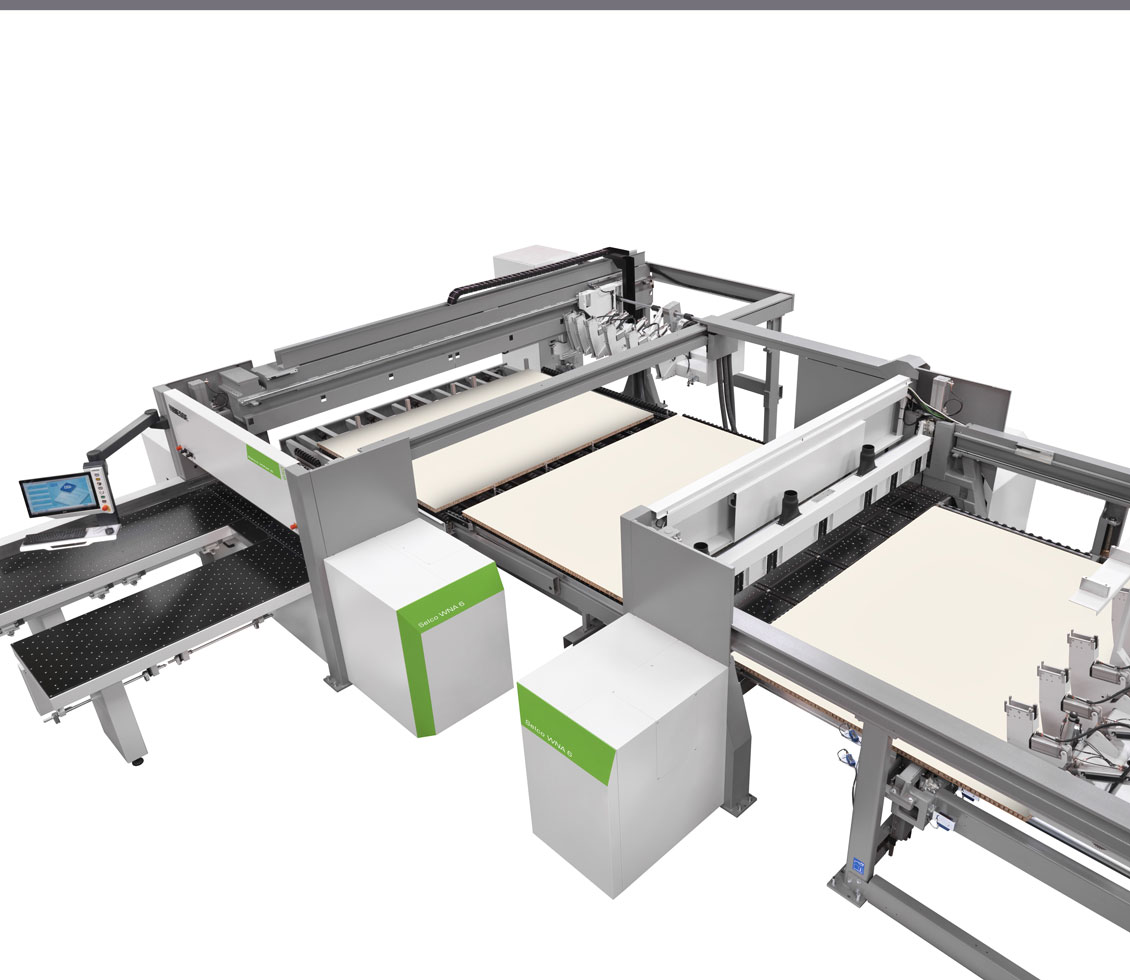

Reduced working dimensions and maximum performance

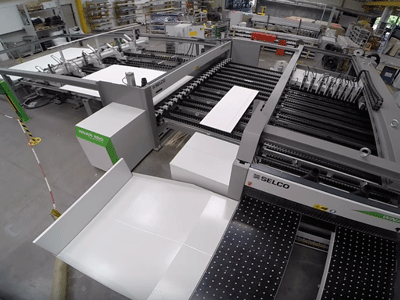

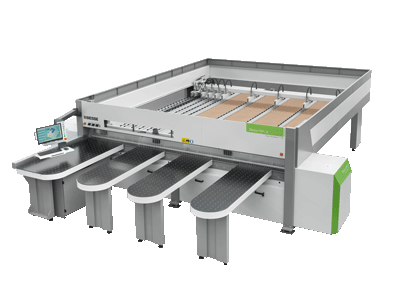

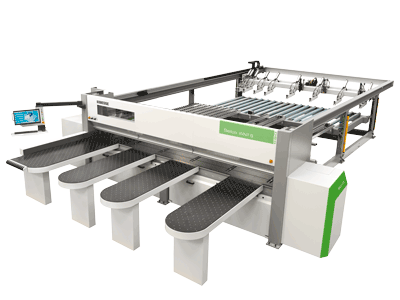

Selco WNA 6 is a range of cutting systems offering two fully independent cutting lines with automated loading that respond to the requirements of the furniture and semi-finished product industries. Selco WNA 6 is an innovative solution that is ideally suited to small and mediumsized companies who want to automate their production processes.

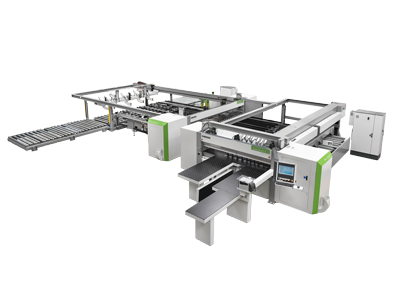

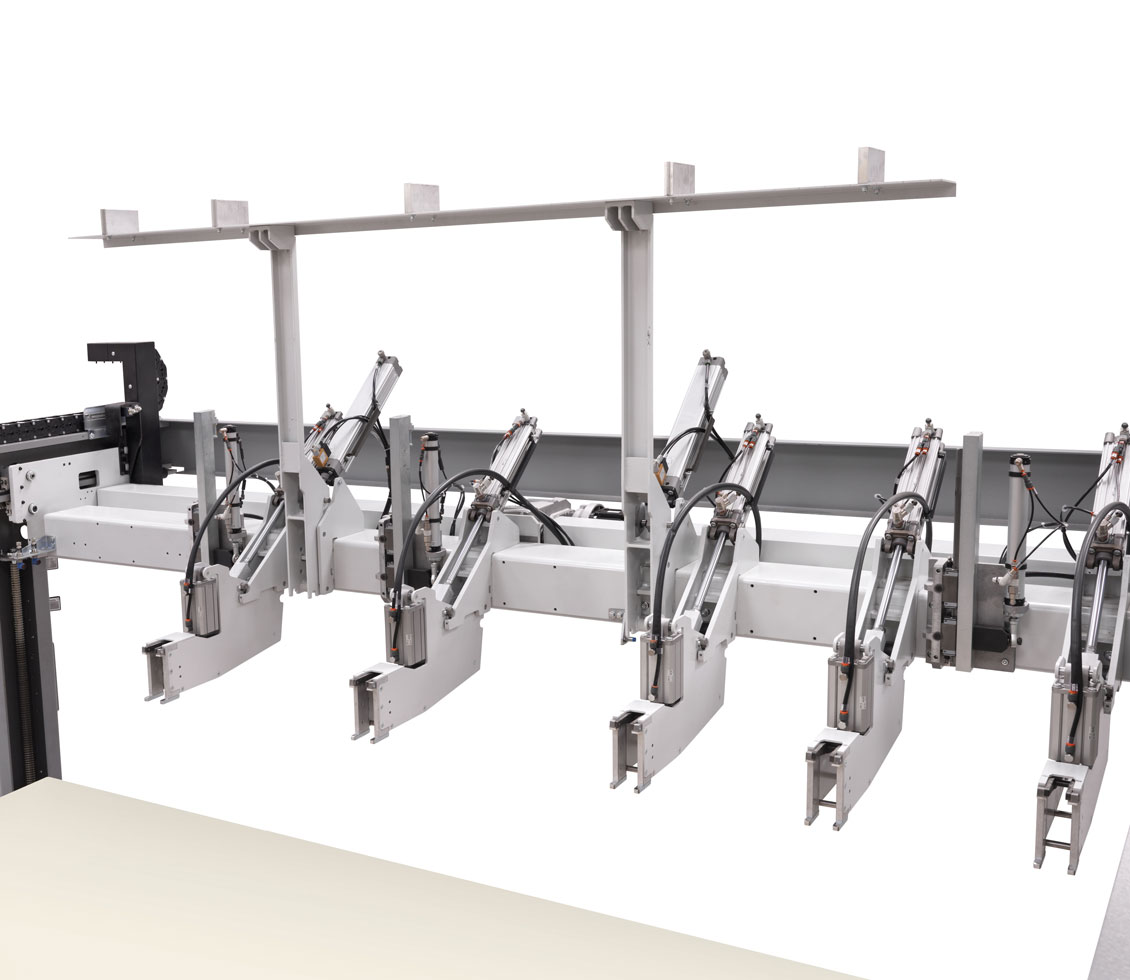

MULTIPUSHER

Significant reduction of processing times thanks to the possibility of combining the grippers with any type of cutting patterns in a single cycle. Device for simultaneous execution of

staggered cross cuts, made with two completely separate pushers. Each pusher can choose to select two idle slave grippers (not powered) completely independently, based on the strips width to be cut. This enables the processing of panels up to 4500 x 2200 mm.

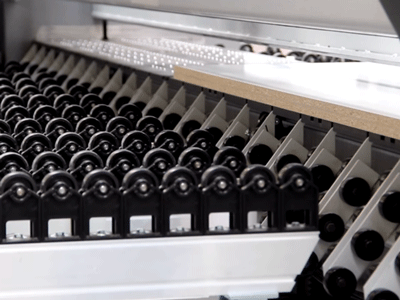

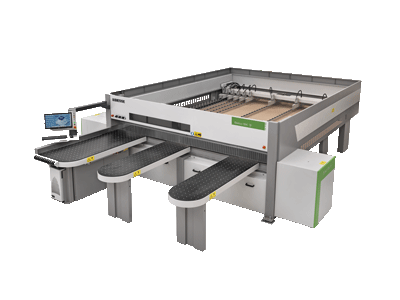

Machining operation precision

The sturdy pushing carriage positions the panels quickly and accurately, thanks to its brushless motor. The slide surface below the pushing device is fitted with independent rollers to avoid marking delicate surfaced panels.

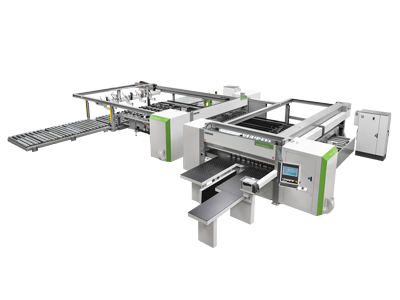

Maximum productive efficiency

The two cutting stations can execute cutting patterns completely

independently, thanks to the presence of an intermediate

zone that can accommodate a whole panel. Both areas

are fully covered in independent rollers to preserve the panels’

surface.

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil