Ron Lyrek is a big believer in being an early adopter of new equipment, software and technology. But it’s also the people component of his company that has made Interscapes Architectural Woodworking an enduring success. Fortunately for everyone involved, people and technology go hand-in-hand.

Four years ago, Lyrek and his wife purchased a 36,000 square-foot building to accommodate the growth of their 32-year-old company. They went to the Biesse Campus in Charlotte, N.C. with a goal of replacing their 12-year-old router purchased from another company. Since Interscapes does 90 percent tenant improvement, with 75 percent of jobs requiring a 6-8 week turn, production speed is crucial.

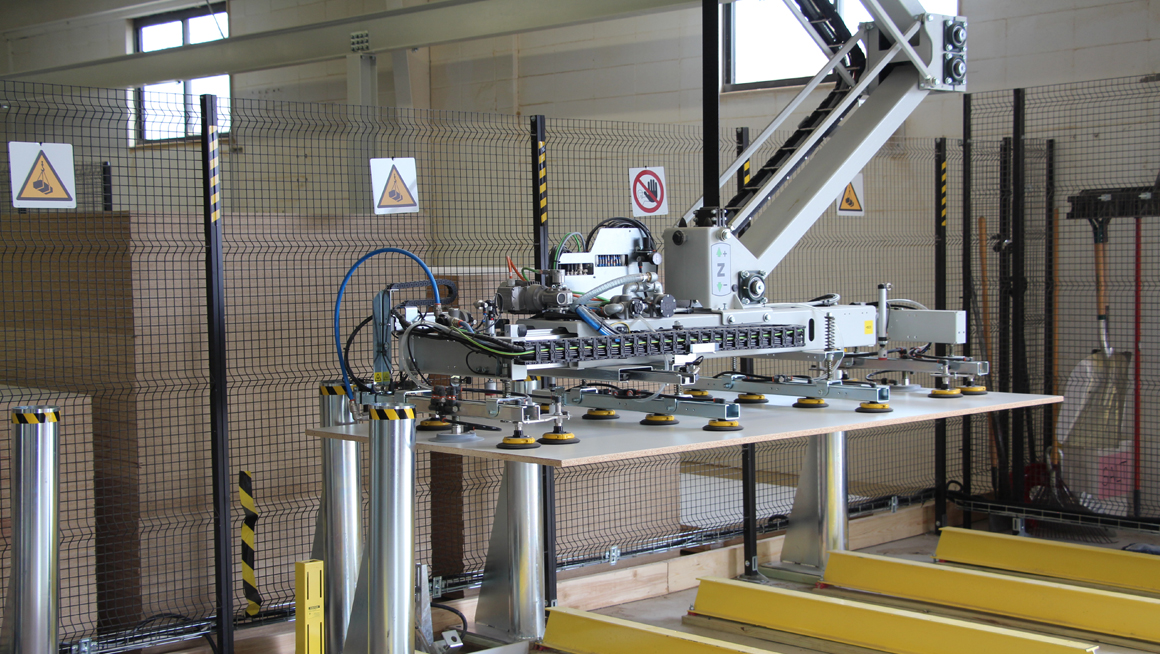

“While we were in Charlotte looking for a router, we saw a Winstore robotic sheet stock storage system in action,” Lyrek said. “It was incredibly cool and fun to watch, but I thought it was a gimmick I would have no use for. I was astounded to learn that it could increase our throughput and almost double the production of our CNC routers. When we realized that we were averaging 4-6 sheets, and we could average 8-11 sheets, it became a no-brainer. Winstore would increase our productivity, help us grow without constraints, save labor, and offer a fast payback. I knew I absolutely had to have it.”

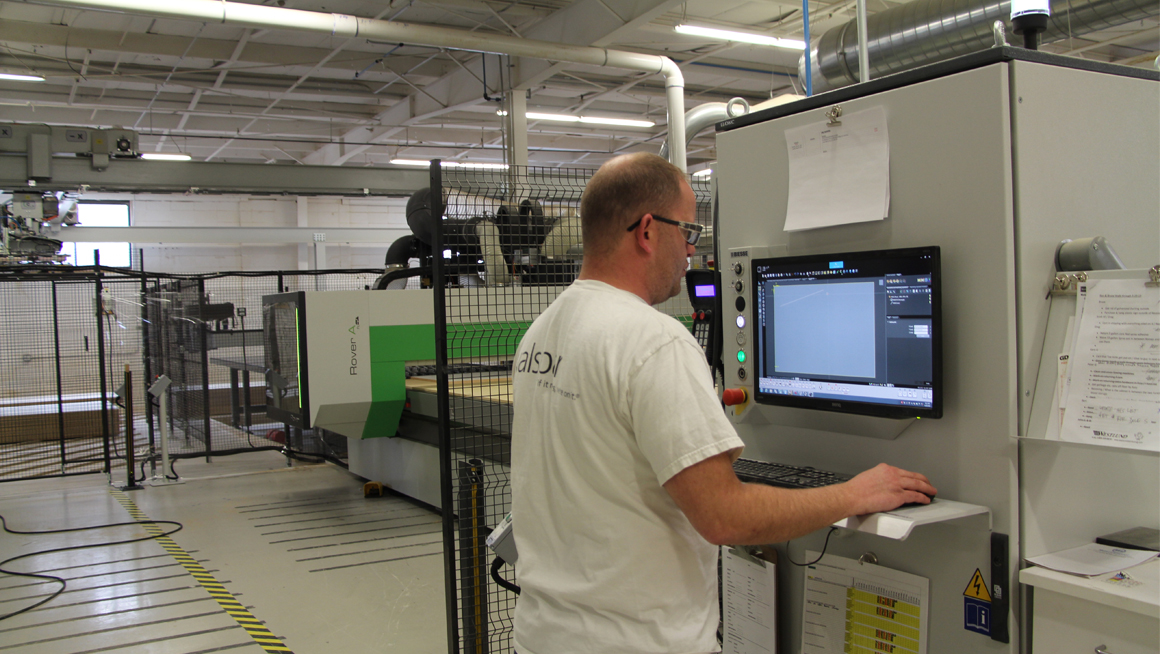

To process solid wood, sheet stock and polymer for cabinets, reception desks and other pieces, Interscapes uses a 2014 Biesse BG 5x12 flat table router and a Biesse Rover A router integrated into the Winstore. “Having the high-speed option and an option for labeling and storing bigger remnants for easy location later has been a big plus,” Lyrek said. “Our Roxyl 5.5 Edgebander has also been phenomenal. The integration was another big part of what I liked about Biesse. Eurosoft was the integrator between Microvellum, Tradesoft and BiesseWorks. Just like we were promised, the installation and software integration worked well.”

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil