We simplify your manufacturing process to make the potential of any material shine.

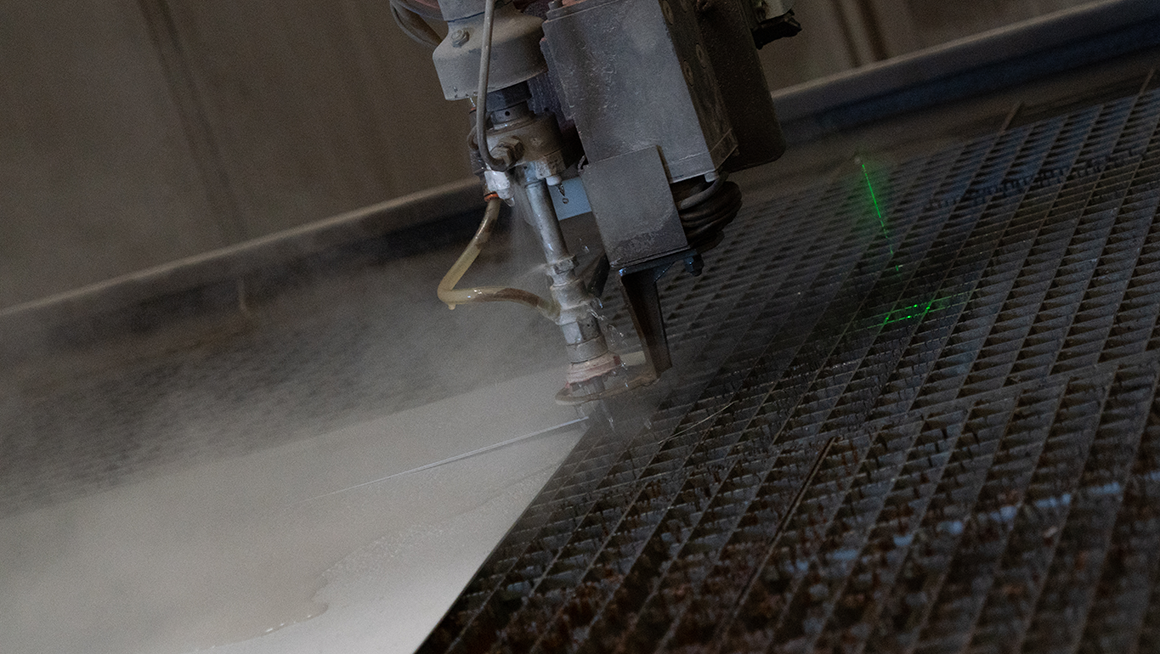

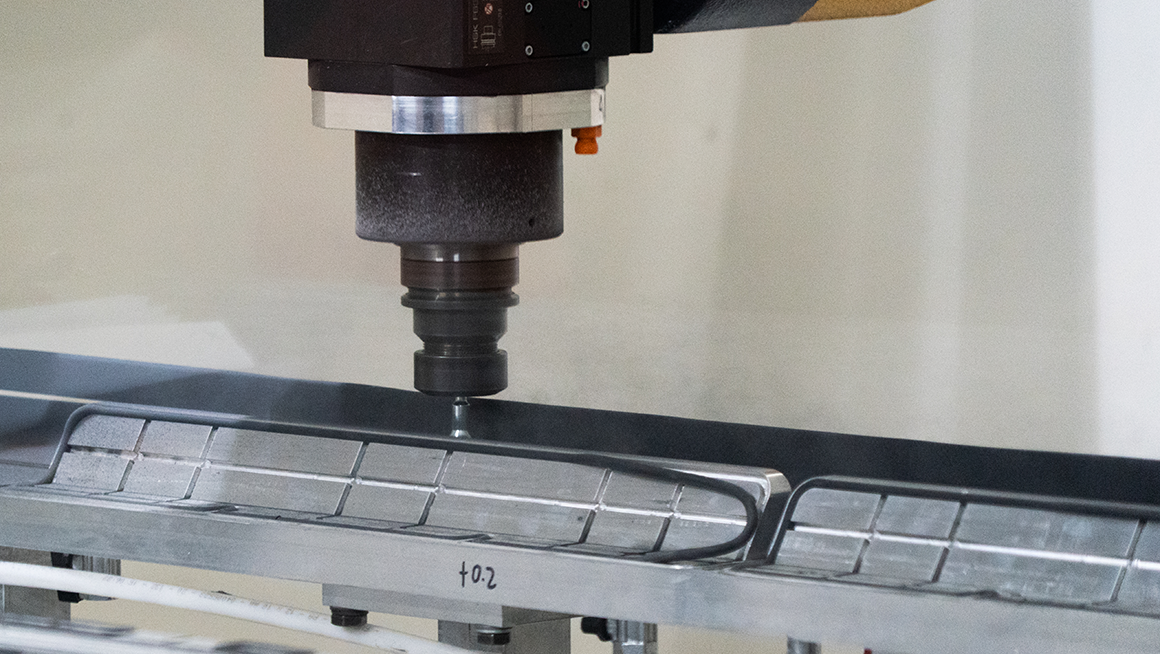

A business strategy based on key points that have grown stronger over the course of three generations - that's what has allowed Tecnologie Avanzate, a company in Veroli (Frusinate), to stand out and make a name for itself in the aerospace sector. This family-run firm is led by Sisto Fini, owner and Sales Director of Tecnologie Avanzate. The company was created from the split of TecnAvan in 2008, after accumulating 20 years' experience, into TecnAvan Interiors and Tecnologie Avanzate, the former specialising in the production and maintenance of components for internal furnishings and special equipment for aeroplanes, the latter in the production and destructive or non-destructive control of aerospace components. “The two companies, numbering 200 employees, are bound together by the same mission: the quality of their components and attention to the environment”, declares Sisto Fini. “Our company stakes everything on quality and competitiveness, without ever forgetting environmental sustainability and the need to look after the local area”, continues Fini. “In fact we focus firmly on social and environmental sustainability, paying the utmost attention to environmental issues and taking care of the area we live in.” The Compounds and Mechanical Machining Division handles the design, development and machining of the compound material - primarily carbon fibre, glass fibre and kevlar pre-impregnated with epoxy resin - by means of cutting, profiling, gluing and polymerisation. In addition, the components are subjected to continuous laboratory tests, dimensional tests and destructive/non-destructive tests.

“We chose Biesse for the degree of precision it guarantees us, even during mechanical machining operations of considerable size, complying with the requirements of the strict product tolerance values.”

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil