For the last 25 years, Adam Plastics has been an industry leader in the supply of Point Of Sale (POS) and retail display units as well as integrated shopfitting solutions. Working mainly with sheet materials such as acrylics, PETG and polycarbonate, the company built up a reputation as an expert in the forming of complex acrylic shapes and bespoke retail solutions. Card and magazine displays, dividers, display cases, holders, shelving units and furniture were its bread and butter.

Biesse’s machining technology - in the form of a Rover 24 purchased 20 years ago and still running today - has been fundamental to the growth and development of the business over the years.

“95% of what we do - whether that is pure machining for a customer or routing sheets so that we can fabricate units - goes through that machine. It is a true workhorse and a lynchpin of our operation,” says Alan Johnston, manager at Vink Scotland’s manufacturing facility.

A shift in focus

Today, although acrylic fabrication remains an important source of revenue for Vink Scotland, the company and the retailscape have changed considerably. Firstly, at the start of 2021, Adam Plastics became part of Vink Holdings - Europe’s largest distributor of plastic products. Secondly, the bricks and mortar retail industry has contracted over the last decade, as consumers have shifted to online shopping. This trend has gone hand in hand with falling demand for retail fixtures, fittings and POS products, prompting the company to look to other markets for future growth.

This diversification has seen Vink Scotland making inroads in a number of markets, but it sees the greatest potential in producing plastic products for industrial applications. These could be anything from wear strips to cogs, shims and gaskets - and are often milled from specialist or performance engineering plastics.

“From a machining perspective, industrial products and retail products are worlds apart. In the retail industry, it is all about how it looks - everything has to be scratch-free and perfectly finished. In industrial applications, aesthetics are secondary to the precision of the machining and the functionality of the product. A part might be going into a factory or on an oil rig so it doesn’t matter how it looks - it is whether it can do its job,” explains Alan.

Time to invest

Last year, with demand from the industrial market building momentum, Vink Scotland decided it was time to invest in a second CNC.

“The reasons were twofold,” says Alan. “Firstly, we didn’t want to get caught out as we recognised that with new build machine lead times at six months to a year, we’d be in trouble if our only CNC went down. Secondly, we were looking to widen the mix of products we were machining and needed additional CNC capabilities if we were to take full advantage of the opportunities that diversification presented.”

Having had a positive experience first time round, when it came to buying a second machine, it made sense to see whether Biesse could meet the brief.

“We looked at other machines, but we felt that the Biesse machines were better made. Biesse’s engineering has always been solid. Buying from Biesse again also made it easier on the software compatibility and familiarity front.”

Four metre table

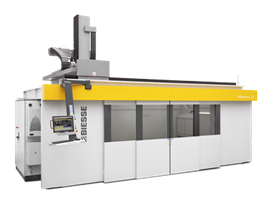

Biesse had a machine with a 4.1m x 2.2m bed in stock, which fitted the bill perfectly. Designed for milling and cutting plastics and composite materials, the Rover Plast K FT is the ideal solution for operations that require ease of use and flexibility.

This model was the perfect choice for several reasons, not least because of the short lead time and the large table.

“We are one of the few machining centres in the country that can cut a 4m sheet,” says Alan.

Vink Scotland also wanted a larger table, as its existing machine has a 3m x 1350mm cutting area, and most materials come as 3m x 2m sheets.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil