Nous simplifions vos procédés de fabrication pour faire briller le potentiel de n'importe quel matériau.

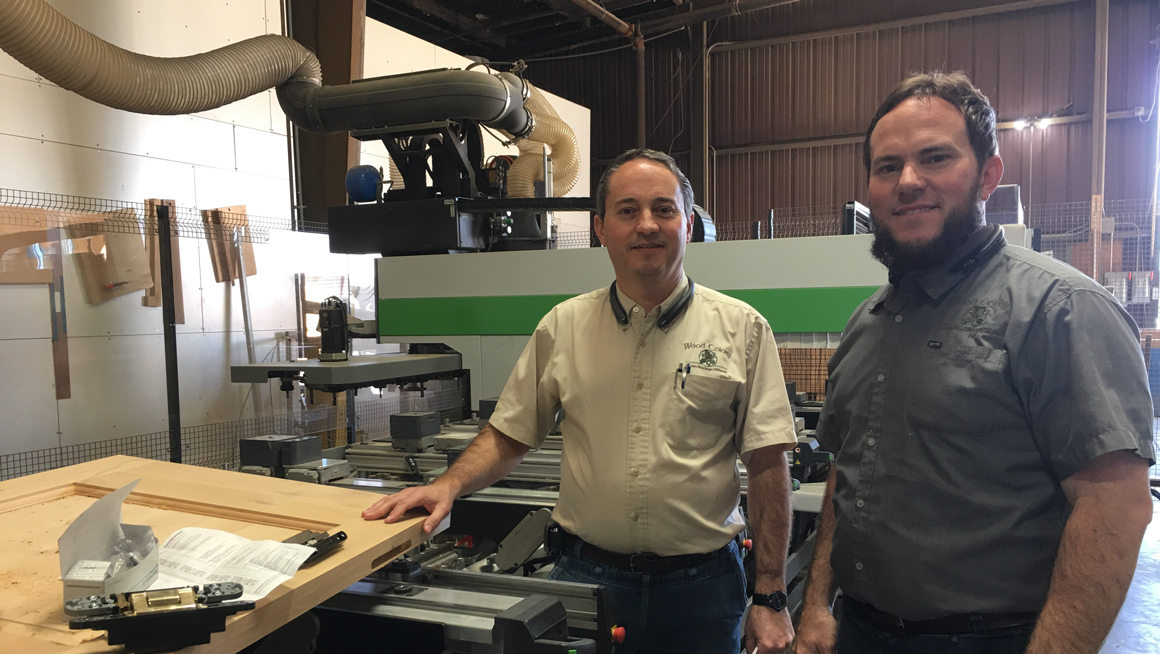

Rover A 5-Axis & bSolid: A Winning Combination for Wood Colony Woodworks

Jesse Overholtzer now oversees the family business and its daily operations out of a 22,000-square-foot facility that includes 10 employees. When Wood Colony was looking for solutions to enhance the company’s custom manufacturing process, they found the answer in Biesse’s Rover A 5-Axis and bSolid software. It’s been a little over a year since Wood Colony introduced the Rover 5-Axis into its manufacturing mix and Overholtzer continues to rave about the benefits of bSolid. “Nothing compares in the software and software’s where it’s at,” he said. “That makes all the difference. We write every day, and with bSolid, we have the capability of bringing it in. There’s nothing better than a person drawing it themselves and machining it to know what it did. I’m a firm, firm believer when you have a computer or software that another company made, and you’re relying on them to nest or make your parts, nothing’s better than me telling the machine every move.”

Because Wood Colony is a custom shop, it doesn’t view high volume of manufacturing as a primary measure of productivity. Rather, the emphasis is clearly on specialization. “We are not based on numbers by any means,” Overholtzer said. “The reason being it’s just such a custom shop. We can get locked into an extensive project up in Atherton in the Bay area and there will be 60 or 70 doors. That can take us a month but it could be upwards of $200-300,000 for that job. It can take some time. We never look at piece count or volume in that regard. We’re very, very specialized.” Wood Colony’s production process is fairly unique in its sector and the Rover A allows the company to manufacture in its own specialized way. The need for a top-performing 5-Axis router has never been greater. “One thing that we do that is really key to us, and there are very few door shops like us that do what we do, we hang all our doors on our machines,” he said.

“One meeting was all it took. I was pretty convinced at that point. I didn’t know a lot about bSolid, but everything I’d seen at that point sounded really impressive to me. Once I got my hands on bSolid, all I can say is, ‘Wow.’”

.png)

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil