Simplificamos el proceso de fabricación para sacar a relucir el potencial de cualquier material.

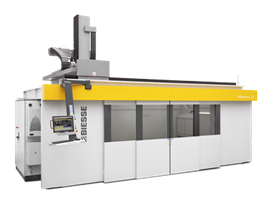

Biesse technologies at Mecspe 2018

We are able to provide specific technology for every manufacturing process, with heightened levels of personalisation according to the type of material processed by the client and the type of component to be created.

"At Biesse, we've chosen to invest in our skills, not only looking to the future, but also anticipating it, in order to remain one step ahead. We create new-generation technologies to facilitate the daily lives of our customers. What was complex in the past, is now truly within everyone's reach. Simplification, increased efficiency, and total reliability are the elements which are at the foundation of our solutions" continued Nazionale.

At the Biesse stand, the expertise of the technical and sales staff are available to provide solid answers to those present. Visitors are also able to request information on SOPHIA, Biesse's IoT platform, created in collaboration with the Accenture consulting firm, which provides its clients access to a wide range of services for simplifying and rationalising the management of their work. It is based on a connection to a cloud service and to special sensors applied to the Biesse machines. The information and data on the technologies in use can be recorded and sent in real time to optimise performance, prevent malfunctions, and increase the productivity of machines and systems. In addition, the direct connection to Parts, the Biesse replacement parts portal, and the chance to upgrade software with just a few clicks, provides clients with everyday work tools that can simplify a host of tasks. The main value of Sophia is the power of its predictive nature: the ability of this technology to provide a vision of the future, anticipating issues that may arise, identifying solutions, and improving performance. The IoT features within the platform guarantee a significant increase in productivity, thanks to a process of constant, accurate, and comprehensive analysis and reporting on manufacturing performance.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil