We simplify your manufacturing process to make the potential of any material shine.

The innovation behind the Uniteam machining centre takes centre stage in the Japanese housing market

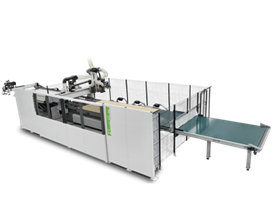

The company produces components for wood houses, structural materials for non-residential buildings up to 3,000 m2 (pre-cut using CAD/CAM), panels and other wood products. "We have a vast range of customers, from builders to woodworkers, and from companies that sell wood to other businesses. Very different companies share a common interest in quality materials machined with the utmost precision, with no errors or defects and limited costs" stated Yukitsugu Takahashi, Sky Corporation president. "What sets us apart from our competitors is our technology, no other company in the sector has a high-tech production process that can compare," Yukitsugu Takahashi continued. In 2015, Sky Corporation purchased a Uniteam machining centre to be able to handle machining that the company couldn't achieve with the equipment it already owned. “Thanks to this new purchase, we are now able to use a machine for machining operations that were previously done manually, thus improving productivity and performance. We are able to process pre-cut panels for non-residential use with Japanese machines, but we use the Uniteam machining centre for longer components, complex joints, and CLT panels, which our previous machines were unable to handle. Thanks to its powerful and efficient CAD/CAM software, the Uniteam has significantly cut the number of cases where manual work was required as well as significantly cutting costs and helping optimise company logistics. Plus, the CAD/CAM software used by the Uniteam can interface with all CAD software available on the market".

Owning this technology allowed us to accept a growing number of orders from customers who are building houses and other structures based on this new technique. It was a wise investment and has helped us grow significantly.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil