Biesse has taken a great step forward in the standardisation of CLT panel machining with its new CLT400 - the high-performance machining centre that's extremely flexible and dynamic.

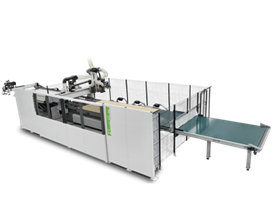

The CLT market has grown significantly in recent years, and it's becoming clear that the best results are obtained by using dedicated technologies in the production cycles. Biesse has taken a great step forward in the standardisation of CLT panel machining with its new CLT400 - the high-performance machining centre that's extremely flexible and dynamic. This machine is designed in particular for medium-large scale companies with significant CLT processing, by offering the most advanced technology and automation for their production. It can be configured to suit machining needs, even with two independent 5-axis HSD electrospindles (65kW) and dedicated tool-holders. These independent electrospindles can meet the most demanding application and production requisites of the sector, working simultaneously on the same piece if necessary (with tool changes made while the machine is running). The work units are extremely powerful and allow quick movements without sacrificing any precision of the machining operation.

Worldwide

Worldwide

Italia

Italia

United Kingdom

United Kingdom

Россия

Россия

France

France

中国

中国

Asia

Asia

Deutschland

Deutschland

España

España

Schweiz

Schweiz

North America

North America

India

India

Australia & New Zealand

Australia & New Zealand

Türkiye Cumhuriyeti

Türkiye Cumhuriyeti

Middle East

Middle East

Brasil

Brasil